Our Services

Product Design and Development

We offer product design and development service, including creating detailed product specifications, conducting feasibility studies, and designing prototypes.

Design for

Manufacturing (DFM)

A core value proposition, our engineers can help review the product design and make recommendations to optimize it for efficient and cost-effective manufacturing. They consider factors such as component selection, assembly processes, and testability.

Compliance and Certification

We can assist in ensuring that the electronic products meet regulatory compliance standards and certifications, such as safety standards (e.g., UL, CE), environmental standards (e.g., RoHS), and industry-specific certifications (e.g., automotive, medical).

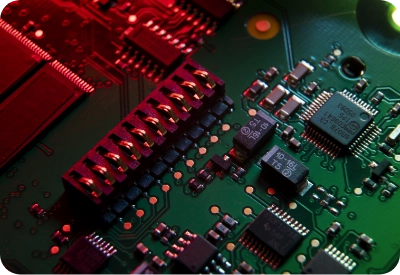

PCB Layout

and Electrical Design

Our skilled engineers who can help you design and lay out printed circuit boards (PCBs) according to the product requirements, and optimize the PCB layout for functionality, manufacturability, and cost-effectiveness.

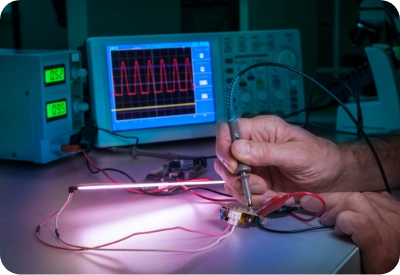

Special Test Development

We can develop and implement procedures and equipment to ensure the quality and functionality your products, such as functional testing, in-circuit testing (ICT), flying probe testing, automated optical inspection (AOI), and other specialized tests based on your requirements.

Software Design

We have a team of software engineers who can design and execute on firmware development on embedded systems or microcontrollers, mobile and web applications, UI desgin, and software integration. In addition, we can help do software testing and documentation as well

After Market Service

In case of product failures or quality issues in the field, we can perform failure analysis to identify root causes and propose corrective actions. We also offer rework and repair services to rectify any manufacturing defects.

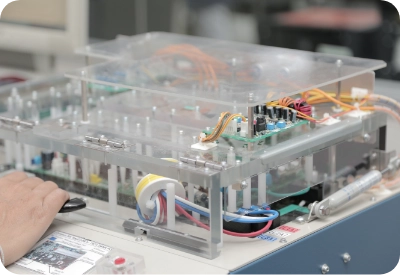

Prototyping (NPI)

We have the capabilities to support prototypes of electronic products (or New Product Introduction, NPI), which involves assembling and testing a limited number of units to validate the design and functionality before mass production.

Validation Testing

We continuously work on improving manufacturing processes to enhance efficiency, reduce defects, and increase throughput. This involves process engineering, equipment optimization, and implementing lean manufacturing principles.

Supply Chain Management

Our expertise in supply chain management, including component sourcing, inventory management, and logistics, can help reduce costs, improve lead times, and ensure a reliable flow of materials.

Capabilities

Your products are evolving to shape the future, and we’re here to help. That’s why we are constantly expanding our in-house capabilities to better deliver innovative, high-quality, and cost-effective solutions to our clients. These are the capabilities we’ve fully integrated into our product development service.

3D printing & prototype

Metal Sheet Fabrication

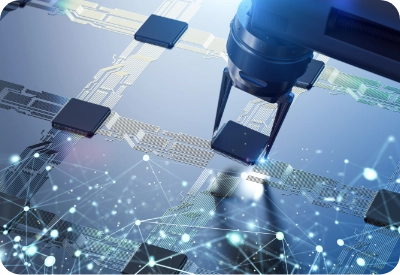

SMT

Online Data Collection

Contact Us

Let us know how we can help you or if you have any questions about our services.